TRU TEMP® 2ND GEN process expands on our original, patented TRU TEMP® XL black oxide with more features and expanded finishing capabilities. See finished examples gallery.

You asked us for a darker and cleaner finish. TRU TEMP® 2ND GEN delivers on that and more. The new patent pending TRU TEMP® 2ND GEN mid-temperature black oxide is a re-engineered and improved finish based on the original and widely used TRU TEMP® XL introduced in 2001.

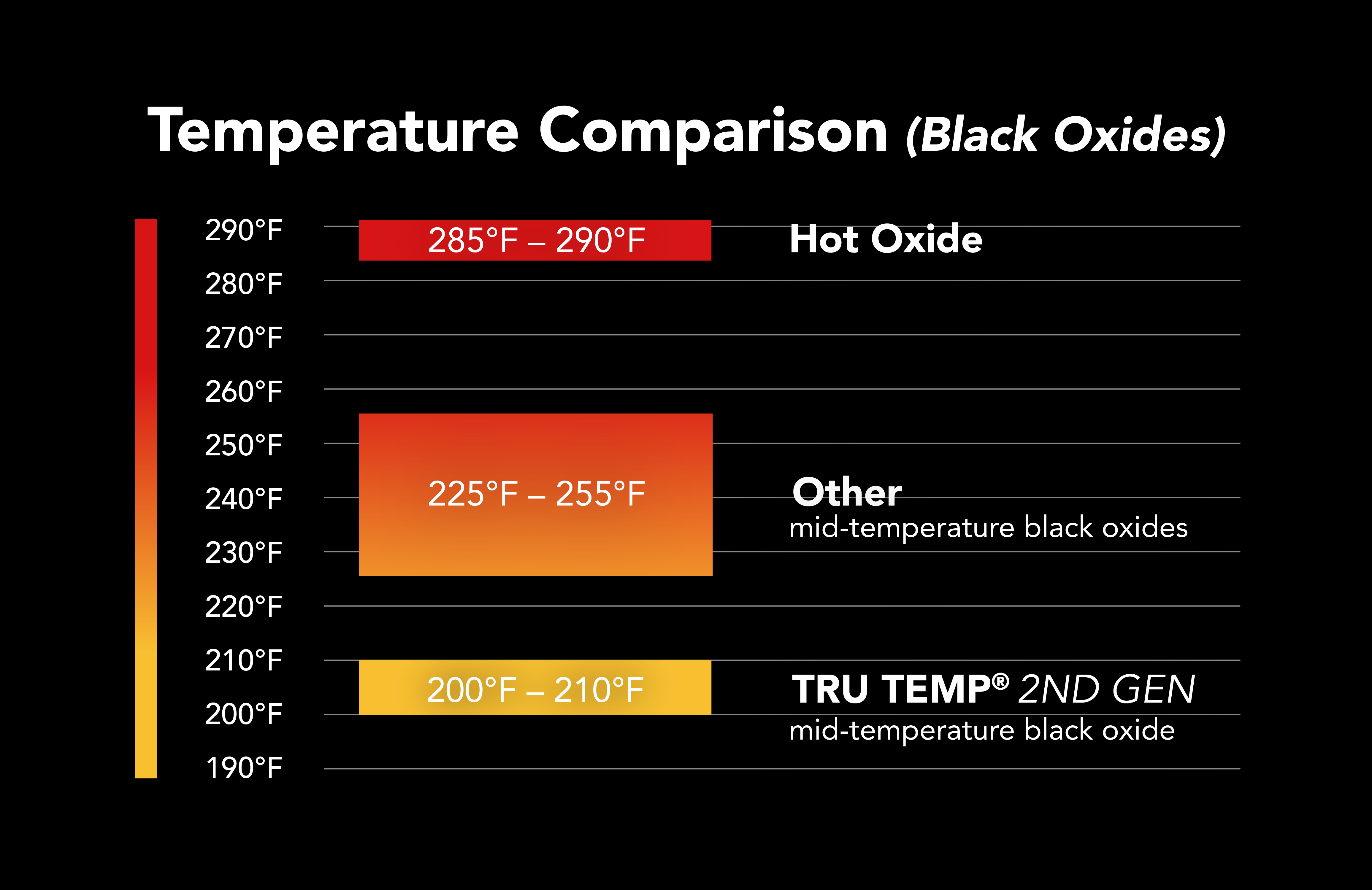

Operating at the same safe temperature range of 200° – 210°F, TRU TEMP® 2ND GEN achieves a superior dark black finish that will not rub off when handled. The clean-to-the-touch magnetite coating is non-dimensional (1 micron thick) and ideal for machined components, non-machined components, powdered metals, MIM, tooling, gears, sucker rods and more.

The patent pending TRU TEMP® 2ND GEN easily blackens an expanded range of high-alloy/high-strength steels and iron in a single pass. Robust features of TRU TEMP® 2ND GEN include protecting critical surfaces in storage, shipment and startup while resisting galling and aiding with break-in lubricity. The process also avoids problems seen with traditional Hot Oxide such as: coatings appearing red or salt leaching problems commonly seen in blind holes or recesses.

TRU TEMP® 2ND GEN in-house process makes it easy and fast to supply customers just-in-time requirements. By using an in-house finishing system, a company can achieve cycle time reductions, inventory reductions and overall process improvements. ISO accountability is enhanced and TRU TEMP® 2ND GEN meets compliancy initiatives including Mil-DTL-13924F Class 1 for steel.

Plus, the process can be designed around several factors including: mix of alloys, hardness and reactivity, condition of the surface prior to blackening, parts handling employed, and the final finish requirement in terms of appearance, gloss and corrosion resistance.

Operates at an optimum 200° – 210°F temperature range making it easy to use in-house and operator friendly. The chemistry is easy to manage and contains no EPA regulated metals, so rinse waters are generally sewerable by neutralizing the pH with a typical discharge range of pH 7-11. Additionally, reaching this range takes only 20% of the acid and is much less dangerous to do yourself than other processes. Since TRU TEMP® 2ND GEN process requires no effluent treatment, the initial capital investment is only about half of other blackening systems.

The most common finishing line configuration completes the blackening in 30-35 minutes in a seven-step process which includes: clean, rinse, activation, rinse, blackening, rinse, and sealing. Alternate process designs can be accommodated for most workflows.

Let us test finish your parts. Call 952-937-7931

TRU TEMP® 2nd Gen Mid Temperature Black Oxide Process operates at 200 – 210° F and forms a durable black oxide finish. True magnetite finish, AMS and MIL spec certifiable.

Mid-Temperature Black Oxide for Iron and steel. Creates a satin black magnetite coating. Ships by LTL services.

Includes:

Chemistry: (enough to fill twice)

Safe Scrub® ST Heavy Duty liquid cleaner 2 Gal

Oxyprime® XPL Heavy Duty Liquid 2 Gal

Tru Temp® 2nd Gen black oxide concentrate 5 Gal

Dri-Touch® Amber IRP2 rust preventative 5 Gal

Equipment:

Steel Pail 3 Ea

Lid for Steel Pail 3 Ea

Plastic Pail w/Handle 4 Ea

Lid for Plastic Pail 1 Ea

Hotplates (110V/1100watt) 2 Ea

NEW:

8” Stainless Steel Tank Thermometers 2 Ea

8” Polypropylene Dipping Basket 1 Ea

NOT FOR SALE IN CALIFORNIA