Low Temperature.

Low Caustic Content.

High Performance.

High Quality Stainless Black Oxide.

The new TRU TEMP® Stainless black oxide finishing process is used as part of a two-stage chemical reaction, beginning with an activation step with a dilute muriatic acid solution. The stainless-steel surface is then oxidized to form the uniform black coating that can be sealed with an appropriate rust preventive topcoat for optimum appearance and corrosion resistance.

“We tried many ways to black oxide stainless steel but always fell short. But Birchwood got it right – it’s dynamite”, stated Steve D’Alfonzo, president of American Metaseal. “Zach Johnson at Birchwood is so helpful and got us going with the new Tru Temp Stainless black oxide and it has helped us pick up new customers.”

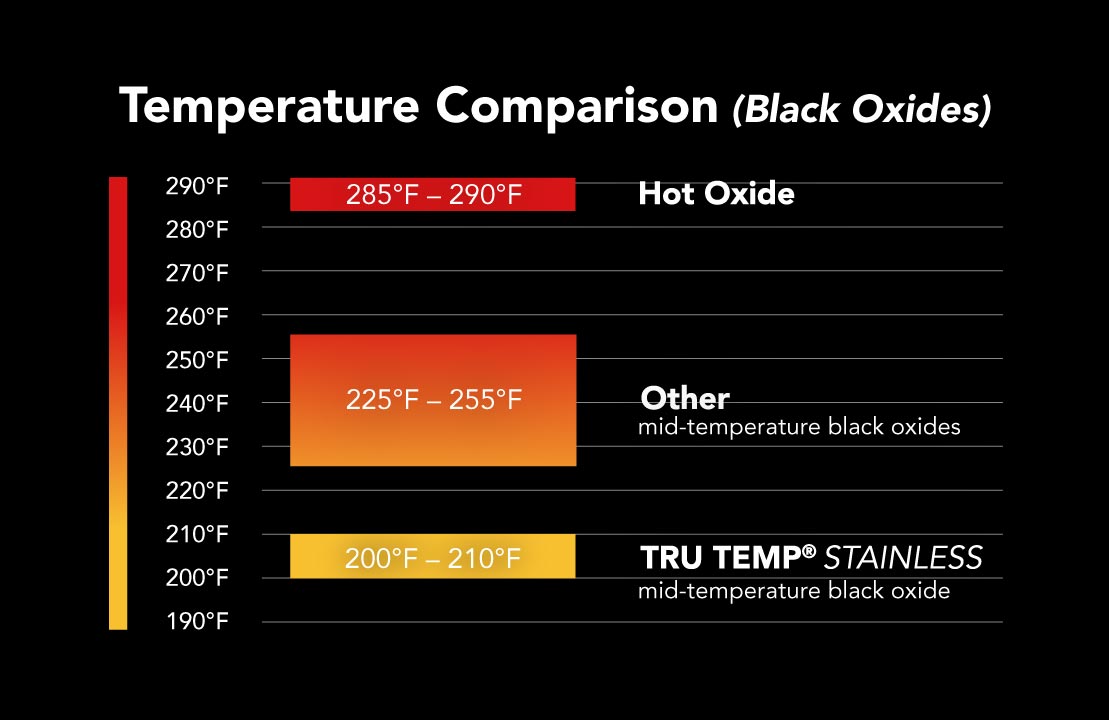

Operates at an optimum 200° – 210°F temperature range making it easy to use in-house and operator friendly. Other stainless black oxides operate at a much higher temp range between 250° – 260°F, making TRU TEMP® Stainless preferred finish as it never reaches boiling/splattering temp.

The most common finishing line configuration completes the blackening in under an hour in a seven-step process which includes: clean, rinse, activation, rinse, blackening, rinse, and sealing. Alternate process designs can be accommodated for most workflows.

Let us test finish your parts. Call 952-937-7931

TRU TEMP® Stainless Mid Temperature Black Oxide Process operates at 200 – 210° F and forms a durable black oxide finish on stainless steel alloys.

Tru Temp® Stainless Black Oxide for stainless-steel substrates forms a black magnetite finish. Ships by LTL services.

Includes:

Chemistry: (enough to fill twice)

Safe Scrub® ST Heavy Duty liquid cleaner 2 Gal

Muriatic Acid Surface Conditioner 2 Gal

TruTemp® Stainless black oxide 10 Gal

Dri-Touch® Amber IRP2 rust preventative 5 Gal

Equipment:

Steel Pail 3 Ea

Lid for Steel Pail 3 Ea

Plastic Pail w/Handle 4 Ea

Lid for Plastic Pail 1 Ea

Hotplates (110V/1100watt) 2 Ea

NEW:

8” Stainless Steel Tank Thermometers 2 ea

8” Polypropylene Dipping Basket 1 ea

NOT FOR SALE IN CALIFORNIA