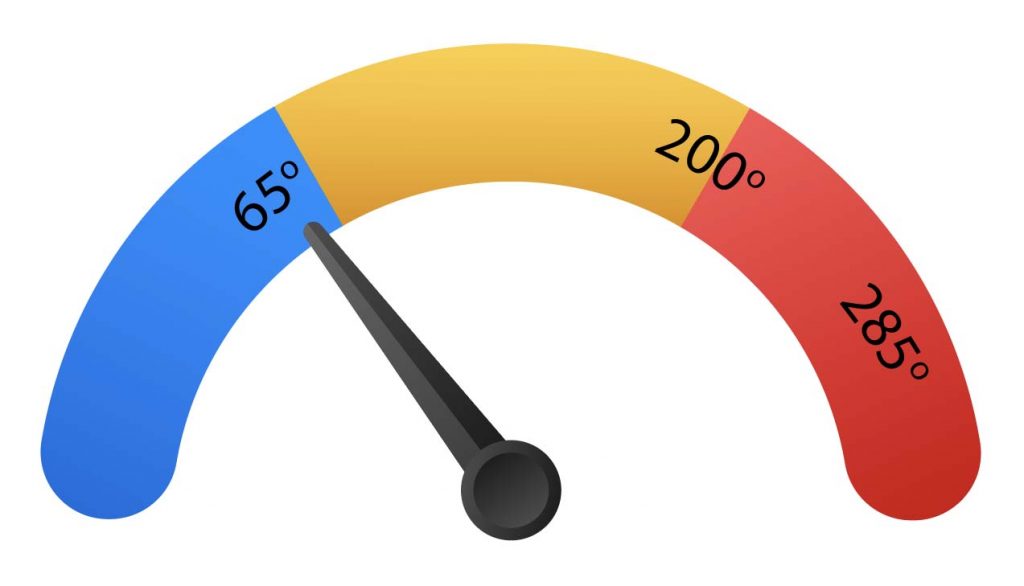

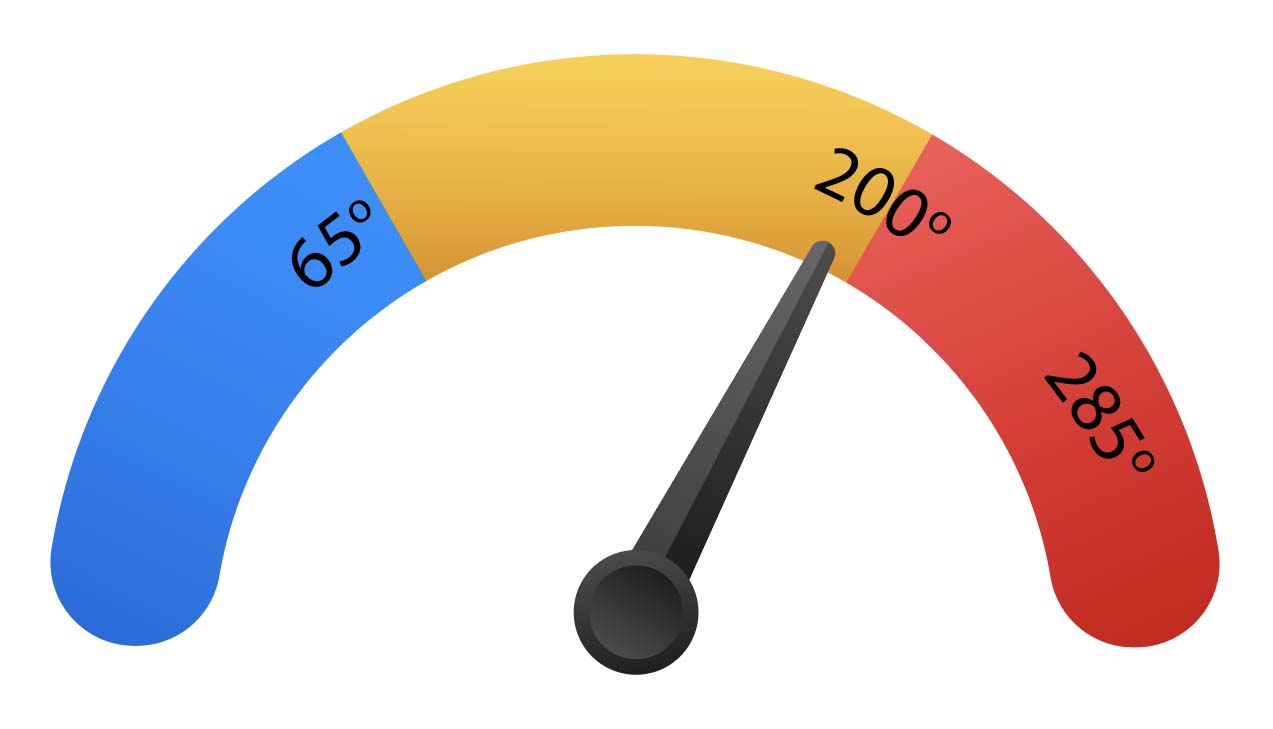

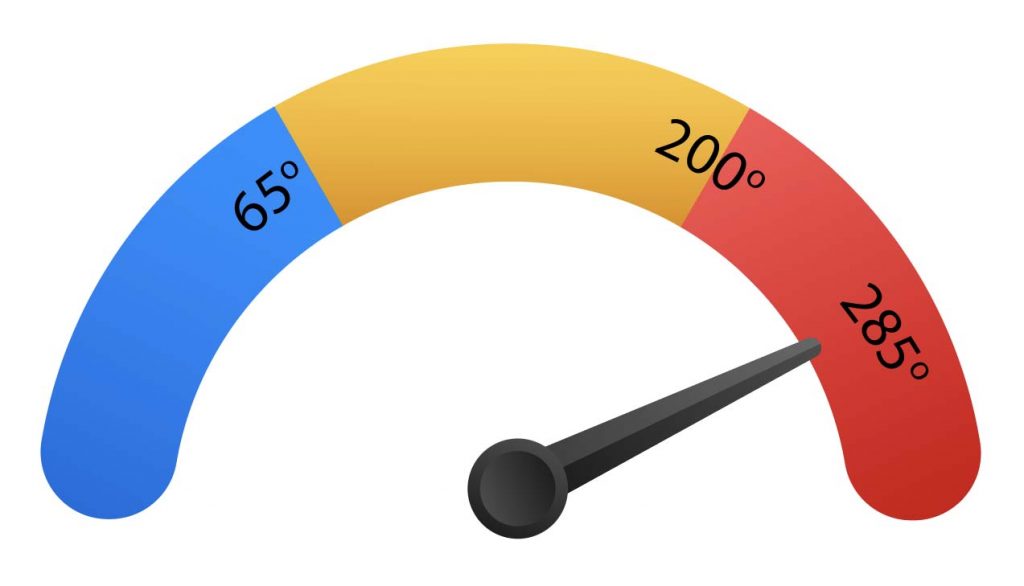

Birchwood Technologies offers a variety of black oxide processes, otherwise known as metal blackener coatings. Black oxide works at three basic temperature ranges from 65° up to 285° F. The black oxide coating is created by a chemical reaction that takes place on the surface of the metal. The resulting black oxide surface creates major advantages over paint coatings and in many cases has become the preferred coating method for iron and steel components for these advantages:

Room-temperature blackening (65° to 85° F), also referred to as cold blackening, is a preferred low cost in-house blackening process due to safe operation. It offers an excellent way to achieve good corrosion protection and enhance sales appeal. The porous crystalline structure of the black finish has a uniform 0.000030 inch (1 micron) thickness.

Products: Presto Black

Mid-temperature black oxide (200° to 210° F) operates at substantially lower temperature than traditional hot black oxide (temp 285-290° F) with a comparable finish. It has become an ideal replacement for hot oxide due to safer operation and lower heating costs. Forms a black magnetite (Fe3O4) finish on all iron and steel parts, not including stainless steel.

Products: Tru Temp

Traditional Hot-temperature black oxide (285° to 290° F) operates at the highest temperature of all conventional black oxides. Requires gas-fired burners to maintain constant rolling boiling. This is a conversion coating formed by a chemical reaction produced by the alkaline salt solution and the immersion of the metal parts. This process is usually performed only by highly trained metal finishing companies. Closely monitored chemical balance is required to prevent salt bloom and discolored red-black coatings. Water balance and proper controls are required to prevent steam explosion.

Products: Birchwood Technologies does not manufacture a hot oxide at this time. We developed our Tru Temp black oxide which operates under the boiling point of water and has 1/10th the caustic content as a safer replacement to the extreme operating temperatures for hot oxide.