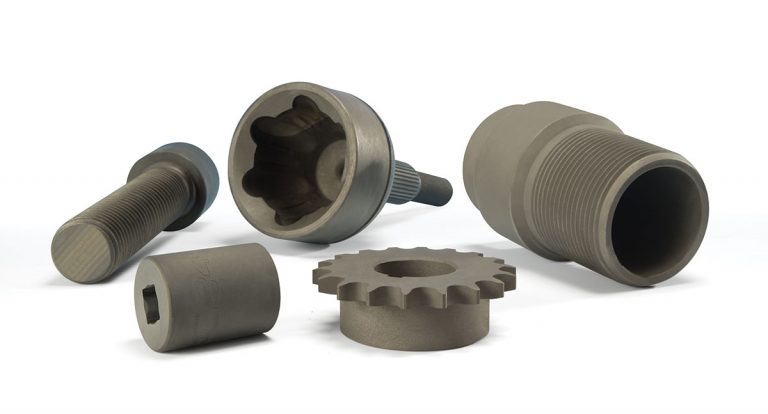

Single process line with Dual Finishing capability and Near-Zero water usage produces mid temperature black oxide finish on these parts using time-proven Tru Temp® process.

Single process line with Dual Finishing capability produces zinc phosphate finished parts using Near-Zero water usage MicroLok® MZN process.

Birchwood Technologies announces its most efficient metal finishing system to date – a dual coating capability contained in a single process tank line. It is safe, simple and inexpensive to operate.

The process line is capable of producing two unique finishes. It produces high quality coatings using the proven Tru Temp mid temperature black oxide process. In addition, the system produces fine-grained zinc phosphate coatings using the MicroLok MZN process. The dual system gives users both finishes that meet many industry requirements and finishing specifications.

Unlike other metal finishing systems, the Tru Temp/MicroLok MZN dual coating line is configured to operate with Near-Zero water consumption. In this way, the user can operate with greatly reduced water consumption where water rationing and governmental discharge permit requirements complicate in-house metal finishing.

This new Birchwood Technologies' Dual Finishing System overcomes water shortage as well as other problems. It eliminates previous pollution hazards, operator safety concerns and high operating costs. Virtually all of the objections to installing in-house metal finishing have been eliminated. It does this while providing the user with high quality Mil-Spec coatings – needed by many OEM manufacturers and job machine shops alike.

The entire dual process system installs easily in the primary shop manufacturing area or in a warehouse area, without interfering with other plant operations. Operators come up to speed quickly with the benefit of on-site factory training thus ensuring safe operation and highest quality results.

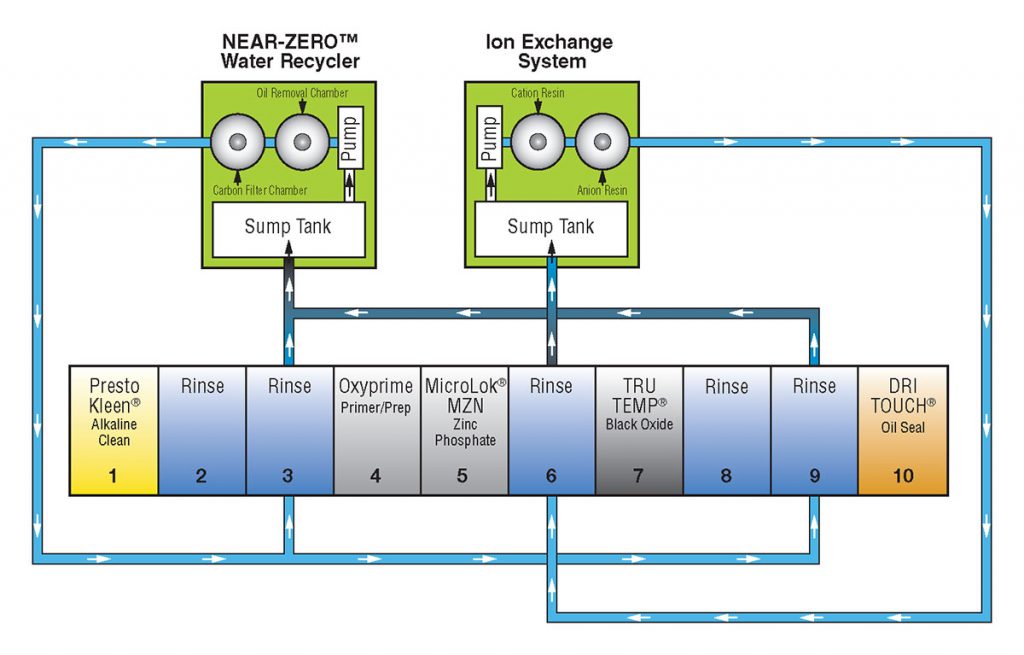

Birchwood Technologies' Dual Process line consists of 10 tanks and the Near-Zero water recycler and Ion Exchange water purifier. Either the blackening or the zinc phosphate process can operate singly or both can operate simultaneously.

Utilizing ten immersion tanks, the system has common tanks to facilitate the most efficient operation of both processes.

Black Oxide parts are processed through stations:

1, 2, 3, 4, 6, 7, 8, 9, 10 - 33 minutes total.

Zinc Phosphate parts are processed through stations:

1, 2, 3, 5, 6, 10 – 28 minutes total.

The two processes utilize the same cleaning step, rinse tanks and oiling station. Rinse tanks #2, 3, 8 & 9 are purified by the Near-Zero™ Water Recycler and re-used. Rinse tank #6 contains zinc (which is regulated by the EPA) and is purified by the ION Exchange System and re-used to prevent zinc from entering the drain. When the rinse tanks or chemical tanks need to be changed for periodic maintenance, the contents can be shipped out using a licensed waste hauler. (Also used by most shops for disposing of cutting oil wastes.)

Both the blackening and zinc phosphate process operate in a single integrated system with no water entering the drain. For this reason, the line can be installed anywhere in the plant or warehouse area.

The Near-Zero Water Recycler for the Tru Temp process collects rinse water from the first rinse tank filtering out free and emulsified oil and detergent residues. The pH of the rinse water is maintained at a near neutral level.

The answer depends on the customer's finish requirements. In the oil and gas drilling industry, for example, there is a need for both processes to finish different down hole drilling components. Similarly, job shop manufacturers with a variety of machined component projects require the specific advantages found only in each of the processes. Here follows the process differences and benefits:

The Tru Temp black oxide process is a patented, mid-temperature system that forms a non-dimensional satin-black finish at 200 degrees. This finish is preferred for components that require a black finish for sales appeal and long-term corrosion resistance without a dimensional change. Operating below the boiling point eliminates the boilover and splattering commonly seen with conventional 290-degre black oxide. Consequently, the process is much safer to operate and contains no EPA regulated chemicals. The Tru Temp finish serves as a direct replacement for the conventional high-temp black oxide and complies with Mil Spec MIL-DTL-13924F, Class 1 and AMS 2485. Tru Temp candidates include tooling, fixturing, power drive components and other parts with tight tolerance machined or ground surfaces.

Alternatively, the MicroLok MZN zinc phosphate is a fine-grained gray finish that has a porous crystal structure to absorb a rust inhibitor topcoat. This finish is preferred for parts that do not require a black finish, but do require long-term corrosion resistance along with anti-galling properties or break-in lubricity. This finish complies with MIL-DTL-16232, Type Z, Classes 1, 2, 3. Typical MicroLok parts include piston/cylinder assemblies, couplings, bushings and other components with sliding/mating surfaces.

ION Exchange processing purifies and recycles the rinse water following the MicroLok processing. The result is pure, deionized water fed back to the rinse tank to be re-used over and over.

The Dual Process line offers the flexibility to operate either process by itself, or both processes simultaneously, as needed. Just one operator can handle all operations with time to spare. One operator can load and unload the system's racks/baskets, process the loads through the line, perform general daily maintenance on the line and produce about 3-4 loads of finished parts per hour. The system's normal motion sequence calls for 2 to 3 loads in process at any point in time, each one occupying a different phase of the process cycle. In this way, the immersion times of the various tanks take place concurrently for maximum throughput. The line can be operated on a full-time or part-time basis, depending on work-flow patterns and part demand. For this reason, the system operator has time available to work other nearby stations to keep his time filled.

| 1. | Ten-tank process line and overhead hoist: | $40,000 |

| 2. | Ion Exchange System: | $25,000 |

| 3. | Near-Zero Water Recycler: | $15,000 |

| Total Capital Outlay | $80,000 |

These costs include follow-up on-site factory training of operators and supervisors covering startup, proper operation and maintenance of the system. It also includes follow-up tech support while the line is in operation.

Using old processes in single process lines, a shop that generates 1,000 pounds of work per day can expect to pay $0.60 to $1.00 per pound (plus freight both ways) when parts are outsourced to a plating shop for black oxide or zinc phosphate metal finishing. The annual total cost would be about $150,000 or more. Turnaround time is usually 3 to 5 days.

By comparison, operating cost for the Dual Tru Temp/MicroLok system including chemicals, labor/burden and utilities total about $0.15 to 0.25 cents a pound or about $50,000 annually. That's $100,000 less than traditional processes.

With these annual total costs in mind, the payback period for the Birchwood Technologies' Dual Process installation would be between 6 to 9 months. The lower operating cost and fast payback are not the only advantages for this in-house installation. For many companies, the most compelling advantage is the capability to offer same-day coating services. By comparison, the longer 3 to 5 day turnaround time for outside coating services can create severe scheduling difficulties.

Here's what happens with many manufacturers. When parts are shipped outside for coating, the value equation is thrown off balance. Most precision components are manufactured on CNC machinery, and achieve 95 percent of their value, often in less than an hour. Shipping those finished parts outside the plant for 3 to 5 days to take on the remaining 5 percent of their value makes little economic sense and creates a huge hiccup in the manufacturing cycle. By performing the final in-house coating operation internally, in about 35 minutes, fits with Best Manufacturing Practices contributing to smooth work-flow and just-in-time manufacturing.

Other benefits are also achieved: fast, same-day shipping times of critical orders (makes key customers happy), lower inventory of finished goods and in-process parts (improves cash flow), fewer purchase orders/invoices to process (eliminates accounting functions) and more streamlined workflow of parts through the plant (reduces tooling changes). These factors are often difficult to quantify but represent significant areas of improvement and cost reduction.

Birchwood Technologies' Dual Process system is regarded as a very "green" coating system with no impact on a manufacturer's pollution liability. The reason is that Tru Temp black oxide solutions contain no EPA regulated pollutants and, in most cases, rinse waters can be sent directly to the city sewer as non-hazardous discharge, with no treatment needed. Operating a Tru Temp line with rinse waters going to city sewer normally results in a monthly water consumption of about 60,000 gallons. By comparison, the Dual Process line configured with the Near-Zero Water Recycler has a monthly water consumption of only 1,000 gallons. This is a compelling reason for installing the system in geographic areas with water restrictions and in plants on septic systems.

Birchwood Technologies' MicroLok MZN zinc phosphate process contains zinc in the coating solution and in the rinse tank following it. Since zinc is regulated by the EPA, the water in the rinse tank is purified and recycled by means of the Ion Exchange System which operates continually to allow the water to be re-used over and over, with no rinse water entering the drain.

By combining the Near-Zero Water Recycler and Ion Exchange water purifying system, the Dual Process line operates as a self-contained system without pollution problems and with no discharge permits needed.

"The Birchwood Technologies' Dual Process system is today's answer to environmentally responsible metal finishing that is efficient and profitable," reports Zach Johnson, Product Manager/Chemistery of Birchwood Technologies. "Manufacturers need to examine new metal finishing technology that streamlines their manufacturing while preserving natural resources and the environment. Our Dual Process system accomplishes that."